Fronius' Cold Metal Transfer for Automotive Welding Process

The Fronius CMT (Cold Metal Transfer) welding process allows users to achieve optimum results when joining different materials, for example steel and aluminium. A wealth of welding benefits for the user. The digital process control detects a short circuit and then helps to detach the droplet by retracting the wire: during welding, the wire.

Cold Metal Transfer Pulse Welding Weld Plus YouTube

This comprehensive review paper examines the Cold Metal Transfer (CMT) welding process and its wide- ranging applications across various industries. With a focus on elucidating the fundamental principles, process characteristics, and recent advancements, the paper offers a comprehensive overview of CMT welding's versatility and effectiveness.

How Cold Welding Works YouTube

The "cold" CMT (Cold Metal Transfer) Advanced welding process from Fronius stands for deposition rates that can be exactly adjusted by way of positive and negative process cycles. As the polarity reversal takes place in the short-circuit phase, this joining process ensures the high stability to be expected of cold welding..

Why We Use Cold Metal Transfer (CMT) Welding

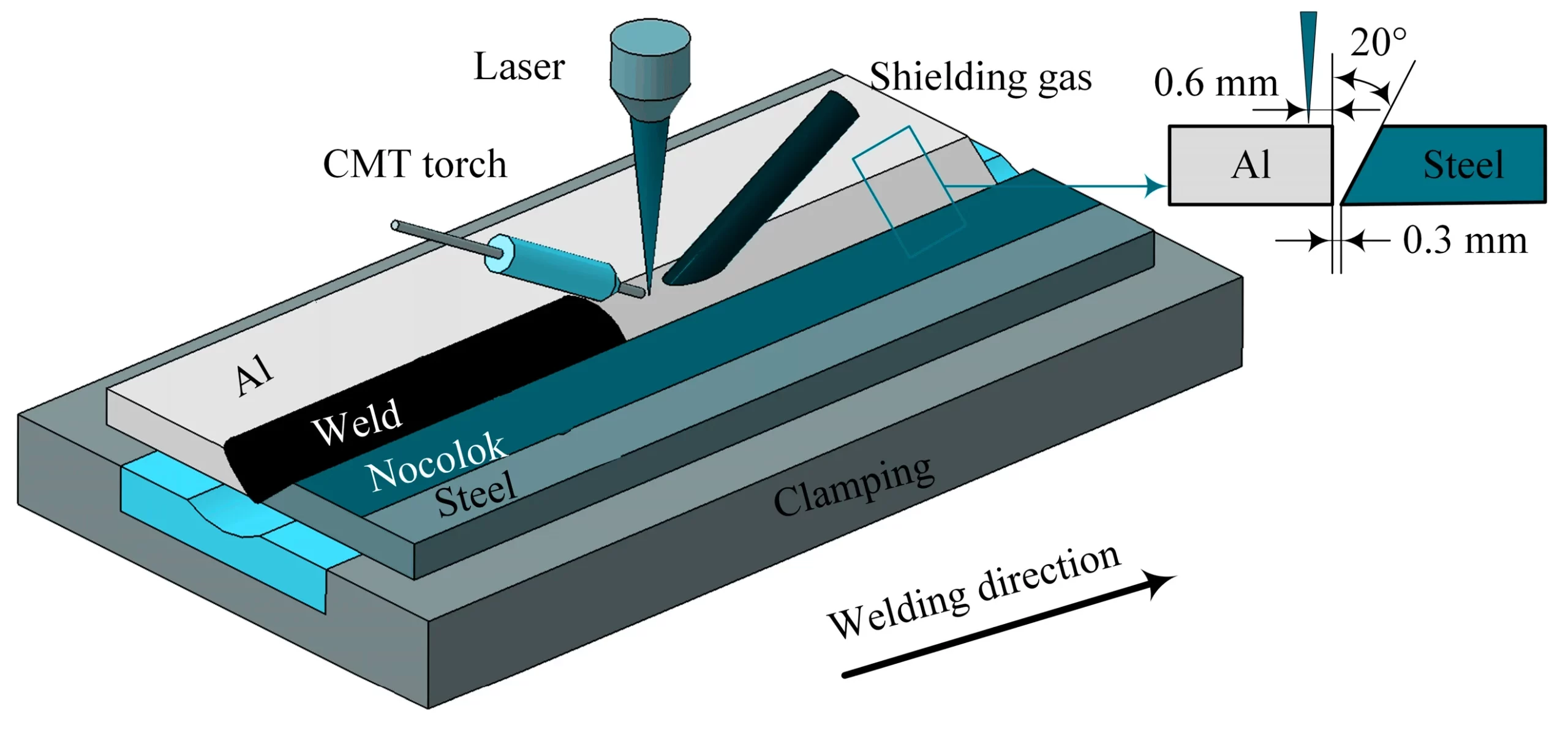

1. Introduction. The cold metal transfer is a modified method of MIG/MAG process. The CMT is a less hot (low heat input) process when compared to the conventional MIG/MAG process [1].The method based on the layer-by-layer principle, which increases the solidification rate, thereby having a fine grain refinement [2].The process parameter for joining materials consists of the welding temperature.

Figure 1 from COLD METAL TRANSFER (CMT) WELDING TECHNOLOGY Semantic Scholar

Cold metal transfer. Cold metal transfer ( CMT) is a welding method that is usually performed by a welding robot. The CMT machine detects a short circuit which sends a signal that retracts the welding filler material, giving the weld time to cool before each drop is placed. This leaves a smooth weld that is stronger than that of a hotter weld.

Cold Metal Transfer (CMT) Welding Protection Gas Visualized CAVILUX Lasers and Schlieren

The entire cold metal transfer process is divided into two states, namely, hot and cold, based on the temperature at the weld zone. The phase responsible for arc generation is called the hot state, while the retraction of the electrode, leading to heat reduction, is termed the cold state [1, 54].CMT is typically conducted using low welding currents, resulting in welded joints with minimal.

Cold metal transfer welding [CMT] How it works

The cold metal transfer (CMT) process basically uses the same system as a Metal Inert Gas/Metal Active Gas (MIG/MAG) system. The CMT process concentrates on welding of thin sheet metal products from stainless steel, aluminum (Al), magnesium (Mg), Mg-Al alloys and dissimilar metals etc. The CMT technology is an alternative to MIG/MAG, providing advantages, such as reduction of distortions, high.

Metal Transfer Process in Welding Lecture33 YouTube

Cold Metal Transfer. Cold metal transfer (CMT) is a fusion welding process that uses a welding arc to create a joint. It's often mislabeled as "cold welding," causing confusion. CMT is a MIG welding process that requires about 90% less heat input than a regular MIG welding process.

Welding Process CMT (Cold Metal Transfer) YouTube

Cold Metal Transfer Dynamic. This process is designed to weld thicker plate. It increases the rate of the wire extension-retraction cycle thus allowing for higher wire feed speeds and consequently, higher deposition rates. This allows for greater penetration into the weld joint, which is ideal for thicker plate.

PPT Let’s Look at the Processes COLD WELDING PRESSURE GAS WELDING ROLL BONDING PowerPoint

2010-32-0071. The cold metal transfer process (CMT) was introduced into industry more than 4 years ago. This process was developed to reduce heat transfer to the substrate during the welding of metals. The CMT process has distinct advantages over the conventional gas metal arc welding process (GMAW), in which the heat input is much greater.

Cold metal transfer plus pulse (CMT+P) process additive manufacturing... Download Scientific

Pickin CG, Young K. Evaluation of cold metal transfer (CMT) process for welding aluminium alloy. Sci Technol Weld Joining 2006; 11(5): 583-585. Crossref. ISI. Google Scholar. 55. Cornacchia G, Cecchel S, Panvini A. A comparative study of mechanical properties of metal inert gas (MIG)-cold metal transfer (CMT) and fiber laser-MIG hybrid welds.

Robotic welding power source upgraded with cold metal transfer process

Process of CMT welding. Using a high-frequency pulse, the CMT transfers molten metal droplets in the weld zone. As the droplet of metal is transferred, the arc is quenched momentarily, minimizing heat input to the workpiece and lowering burn-through and distortion [16].CMT uses "reverse polarity" to create a stable arc at a low current for a better weld.

DTEC GmbH CMT Cold Metal Transfer Welding YouTube

The Fronius CMT (Cold Metal Transfer) welding process allows users to achieve optimum results when joining different materials, for example steel and aluminum. A wealth of welding benefits for the user. The digital process control detects a short circuit and then helps to detach the droplet by retracting the wire: during welding, the wire moves.

Fronius Cold Metal Transfer — Lean Machine Metal Fabrication Inc.

This review paper offers a comprehensive analysis of the cold metal transfer (CMT) welding process in the context of similar metals and alloys. With a focus on recent advancements and key research contributions, the paper synthesizes a wealth of information to provide an understanding of the technique's applicability and potential in welding similar metals and alloys. By delving into the.

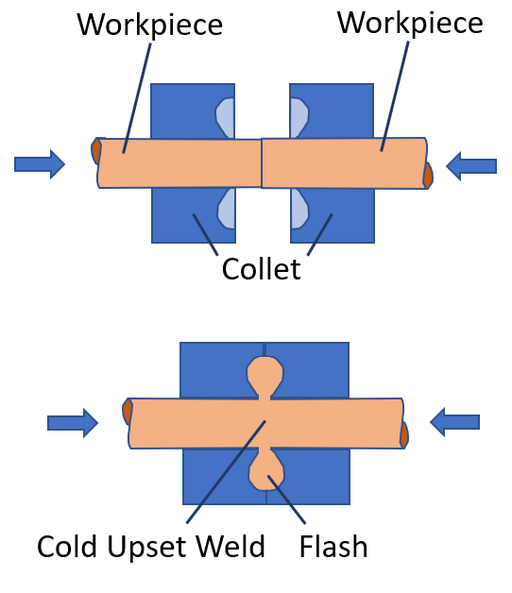

Cold Welding What it's used for and how it works.

Cold metal transfer (CMT) welding is a sophisticated version of fusion welding process available with advanced features incorporated in it. During the process of joining metallic parts with CMT, the bead shape and size have significant effects on the weld quality. Typically, bead geometry is characterized by the three important parameters namely weld width, weld depth and reinforcement height.

Why We Use Cold Metal Transfer (CMT) Welding

Gas metal arc welding. Paul Kah, in Advancements in Intelligent Gas Metal Arc Welding Systems, 2021. 1.5.6 Mechanically assisted droplet transfer. In mechanically assisted droplet transfer, filler wire motion is integrated with the welding process such that the overall motion of the wire is forward but can be reversed at specific moment such that it assists breakage of the molten metal during.

.